Three-D printers can make just about anything — even synthetic bones.

The material, called hyperelastic bone or HB, stimulates new bone growth when grafted to a bone injury site, and its developers say it is perfect for use in developing countries because it is inexpensive and quick to create.

HB is unlike other man-made bone material, which is brittle and hard to work with, or human bone grafts that sometimes don't take hold.

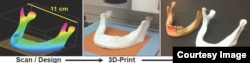

Its biomaterial is made up of minerals found in bones and teeth, and a polymer. The resulting sheet is both highly elastic and strong, and it can be shaped into various sizes and thicknesses, then cut and folded in any number of ways to be sutured for a tight bone graft.

Stem cells are overlaid on HB, which acts as a flexible scaffold. The body readily accepts the highly porous, implanted material, through which new blood vessels form and grow. No growth factors are used to stimulate healing.

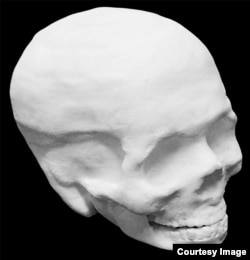

In experiments with animals, HB melded into surrounding tissue in just four weeks, fusing to spines in rats and repairing a skull defect in monkeys. The work is described in the journal Science Translational Medicine.

Many applications

Ramille Shah, a professor in Northwestern University's Department of Materials Science and Engineering, helped develop the technology and sees many applications for it.

"Because of the versatility and properties and ability to print hyperelastic bone in different forms, anywhere from large sheets or hollow or dense structures to simple or complex structures, we envision this material to be used in a variety of orthopedic applications, from fine fractures to sports medicine injuries — as an example, [ligament] or rotator cuff injuries, where soft tissue-to-bone healing is very important — and also different cranial-facial defect applications," Shah said.

Co-author Adam Jakus said there are a number of advantages to using hyperelastic bone, which is very inexpensive to make.

"Production-wise, [it's] very tailorable, very fast," he said. "And then you have this material that pops out [of the 3-D printer]. You don't have to do any further processing of it. You really just need to wash it and sterilize it and package it, and then it can be used."

Because it doesn't require refrigeration, Jakus thinks HB is ideal for use in the developing world, "where you can just ship it way ahead of time, have it on the shelf until it's needed, rather than having to create a complex biomaterial that needs to be heavily refrigerated or frozen. In most of these cases in the Third World countries, those types of facilities might not be accessible."

The authors see hyperelastic material being used in children to repair bones and disfiguring injuries that are socially isolating.

Because the polymers already have the approval of U.S. regulators, scientists hope to make hyperelastic bone available for use by doctors within the next five years.