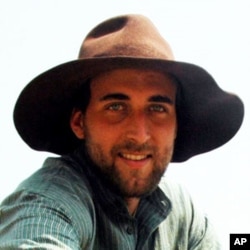

When mechanical engineer Peter Frykman created a low-cost drip-irrigation system designed to improve crop yields for small farmers in India and China, he took a significant step toward achieving his dream of becoming a socially-conscious entrepreneur who makes life better for the world’s poor - while also turning a profit.

As a graduate student at Stanford University, Frykman took a course called ‘Enterpreneurial Design for Extreme Affordability.’ As part of that class, he went to Ethiopia to look for irrigation solutions for small farms. It didn’t take him long to come up with an answer.

Water scarcity

“Drip irrigation was one of the first things that we saw," says Frykman. "These farmers really needed the benefits of drip irrigation - which are water savings and a huge increase in plant yield, but the solutions that were available to them were too expensive and too complicated.”

Frykman returned to Stanford wanting to find a solution. He knew that 90 percent of the world’s farmers grow their crops on two hectares or less and water scarcity is a big problem. How the available water was used only made the problem worse.

“What many people don’t realize is that over 50 percent of our fresh water is used for agriculture," he says. "And in some places, like India and China, it can be as high as 90 percent. And that means that it’s basically pumped to the field and just dumped on the field in flood irrigation.”

Finding a solution

Frykman believed that with efficient irrigation, small-plot farmers could cut their water use while boosting crop output.

So, in 2008, he founded Driptech, a for-profit, social-impact company that produces an inexpensive drip irrigation system. Like large-scale systems, Frykman’s model uses tubing with small holes which delivers water directly to the roots of the plants. The main difference is in how the water is stored and forced into the tubes.

“Most small-plot farmers don’t have high-pressure pumps so our system runs off of gravity pressure" says Frykman. "We can actually run it off of just an elevated tank of water, so it scales down to their needs.”

Sarah Huber, Driptech’s director of business development, just returned from a three-week visit to India and China, the company’s primary markets. She says it’s clear that the irrigation system is having an impact on farmers and the demand for it growing rapidly.

Cost effective

“We’ve seen, with our farmers in China, income increase around 50 percent which makes a dramatic difference in their lifestyle," says Huber, "and their ability to pursue other employment opportunities, send their kids to school, get proper health care and we’ve seen some very big impacts there and there’s so many people in China who need this technology.”

According to Huber, Driptech’s system gives small farmers in India a steady income stream because they no longer have to depend on the monsoons for water and can grow year-round, even during the dry season

Driptech sells its product through local partners - agriculture companies or, in China, the government. Its most popular system in India costs about $150 dollars per quarter-hectare.

Frykman says it pays for itself within six months.

Making a difference

The entrepreneur is proud that Driptech has found a way to manufacture its irrigation system in any country where small farmers can use it.

“We can put everything we need for an entire drip irrigation factory into a shipping container, put it anywhere in the world for about $50,000 and that factory would produce enough drip irrigation for thousands of farms per year.”

From a business perspective, Driptech’s greatest accomplishment is developing a low-cost, small-scale irrigation system with few parts, and easy installation. But Frykman believes his company’s greatest success lies in the number of individual farmers whose lives have been improved.

“To sell a product to a farmer who makes a couple dollars a day it has to be perfect," he says. "And the challenge of designing and delivering that type of product is something that’s really exciting and to see that be successful and see that gain momentum is the most exciting thing for me.”

The next step for Frykman’s company is to increase the size of its local team, hire more partners in China and India, explore new markets, and scale up manufacturing to meet growing world-wide demand.